Welcome To Bryan Die cast products

Quality Zinc Die Castings since 1964

Welcome To Bryan Die cast products

Quality Zinc Die Castings since 1964

About Bryan Die Cast

NEW IDEAS, FROM CONCEPTS TO CASTINGS

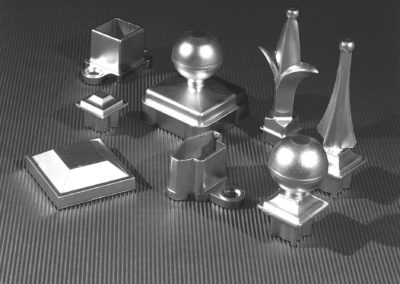

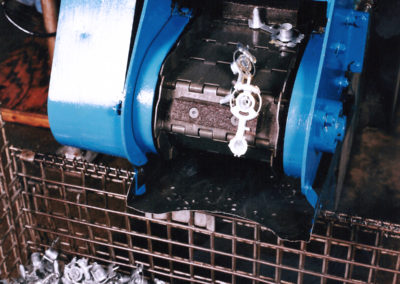

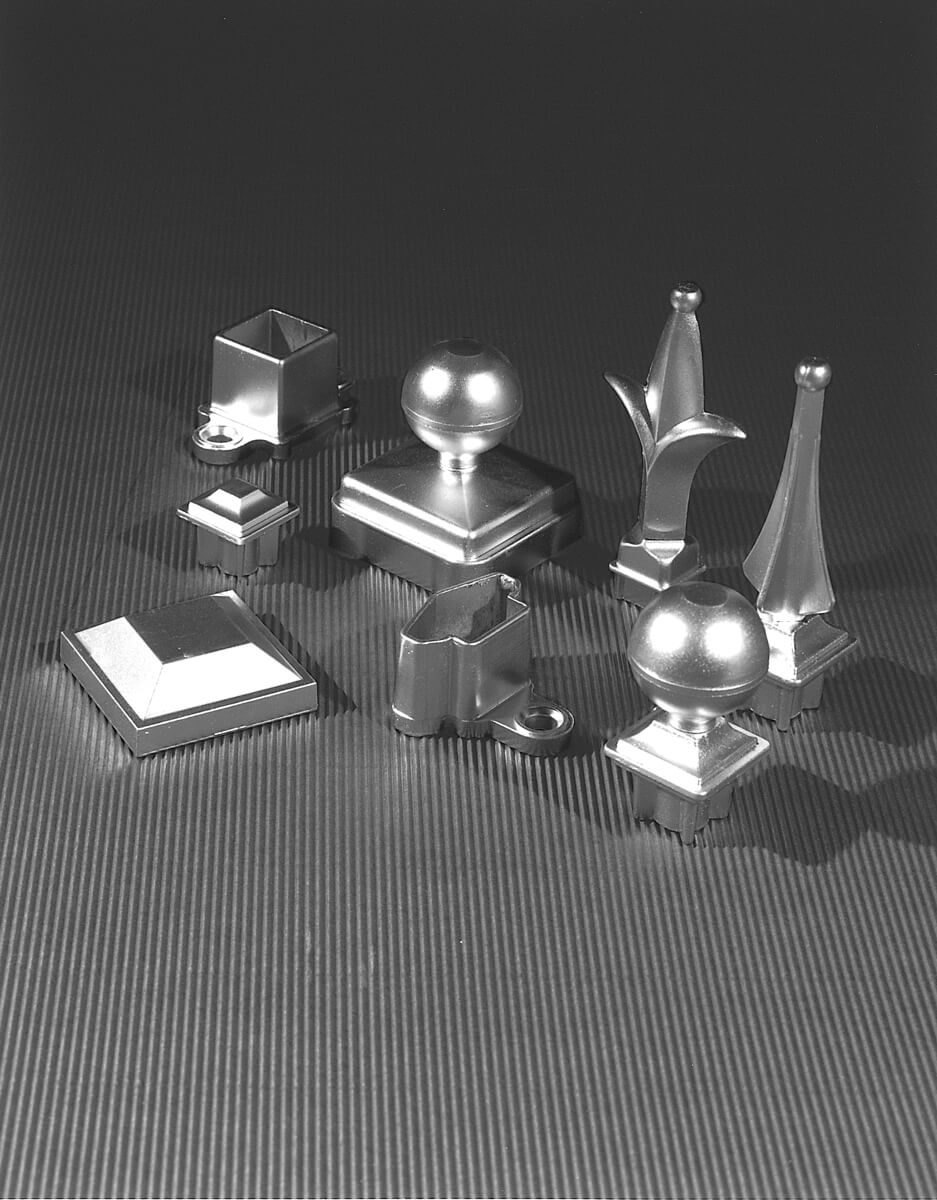

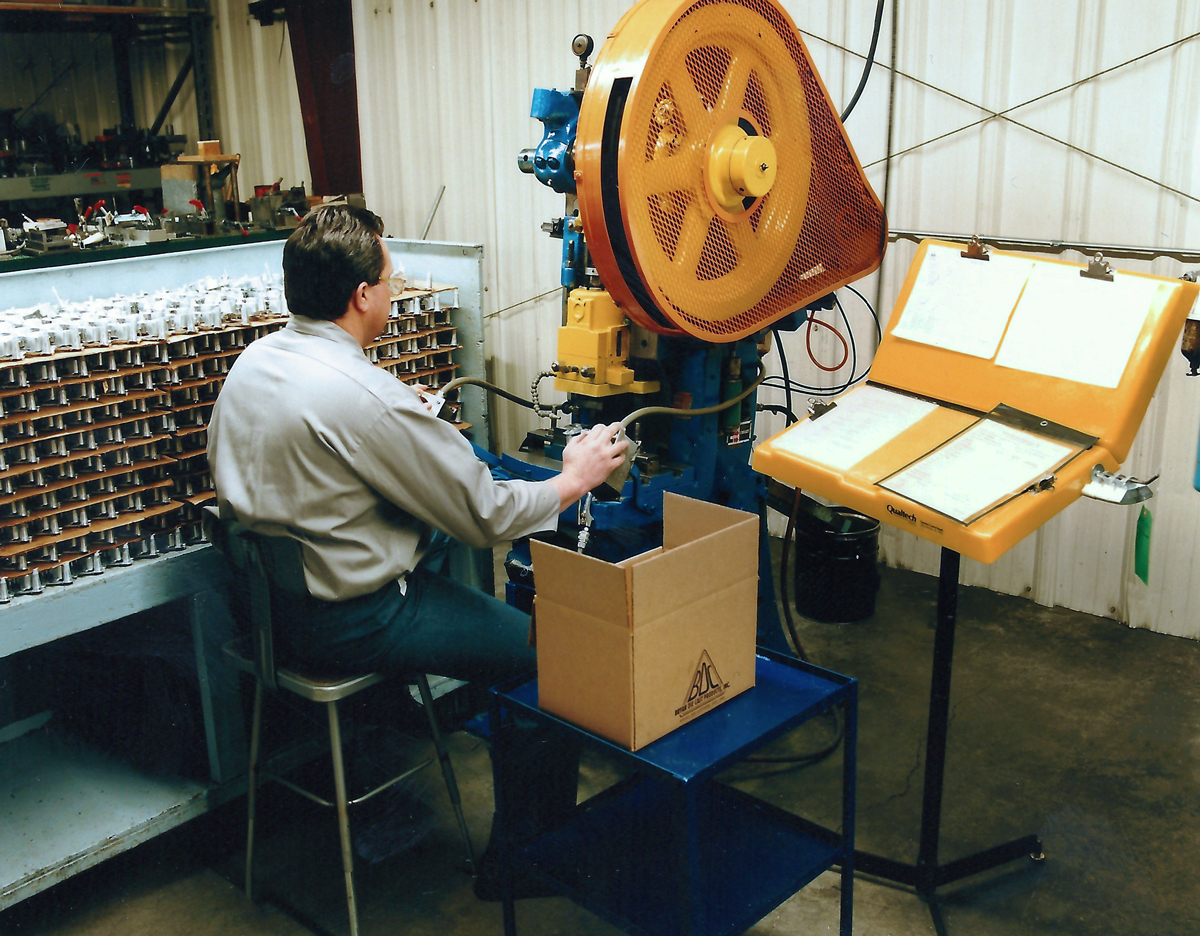

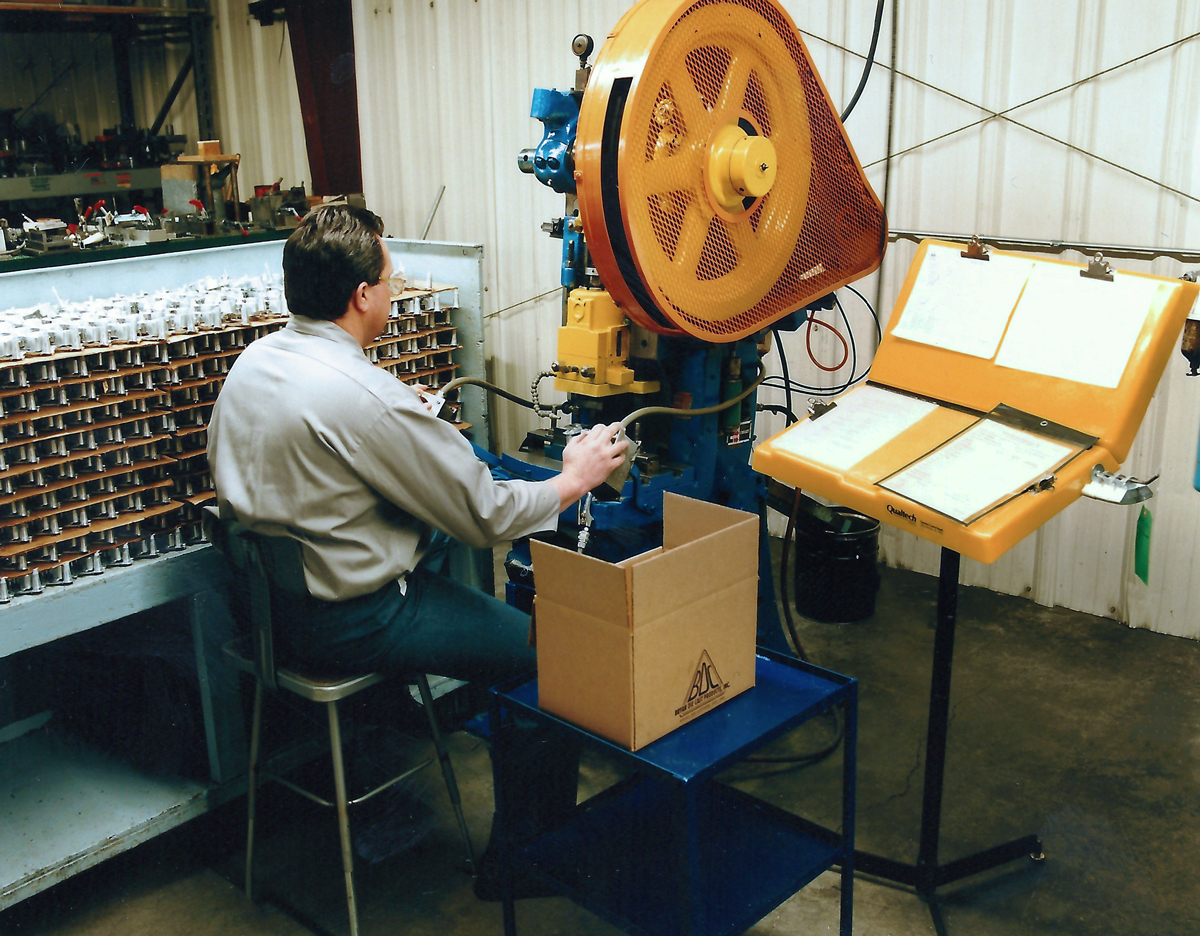

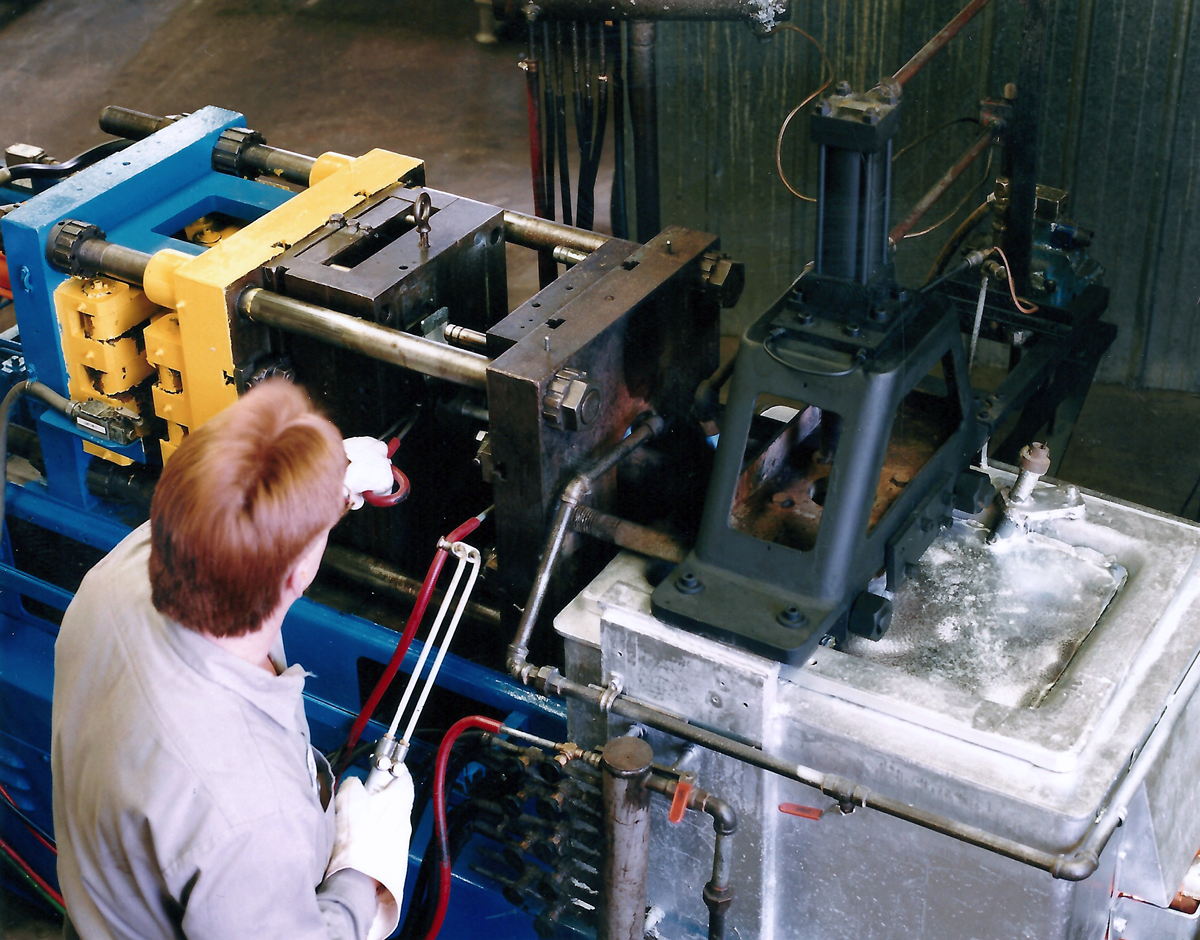

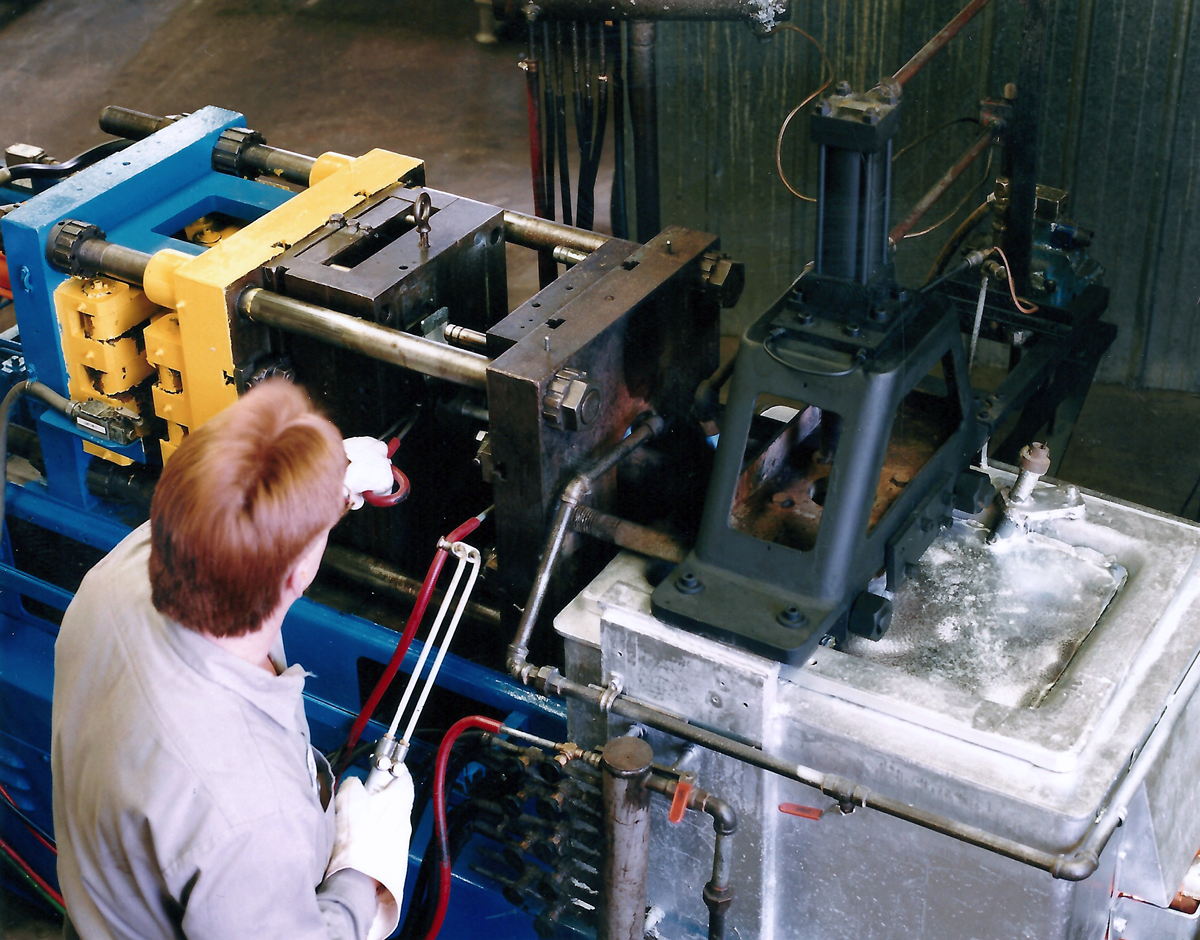

Bryan Die Cast Products has specialized in high-pressure Zinc Die Castings since 1964. We specialize in small to medium size castings ranging from 10 grams to 2 pounds. Casting with zinc alloys allows us to offer our customers a versatile, cost effective, durable product. We currently cast parts for a variety of industries including Fencing, Medical, Appliance and Automotive Industries. We strive for total customer satisfaction and to meet your quality needs and expectations. Based in NW Ohio, our manufacturing facility is strategically located to meet shipping requirements worldwide.

About Bryan Die Cast Products

NEW IDEAS, FROM CONCEPT TO CASTING

NEW IDEAS, FROM CONCEPT TO CASTING

WHY BDC and WHY ZINC

There are a variety of zinc alloys available to meet your casting needs. As one of the most versatile metals for casting, zinc offers a variety of advantages.

- Excellent castability & strength

- Thermally conductive

- Electrically conductive

- Tight tolerance accuracy, dimensional stability, repeatability

- Superb finishing characteristics

- Longer tool life

- Greater efficiencies

- Environmentally friendly and 100% recyclable

- Corrosion resistant

- Cost Effective

WHY BDC and WHY ZINC

There are a variety of zinc alloys available to meet your casting needs. As one of the most versatile metals for casting, zinc offers a variety of advantages.

- Excellent castability & strength

- Thermally conductive

- Electrically conductive

- Tight tolerance accuracy, dimensional stability, repeatability

- Superb finishing characteristics

- Longer tool life

- Greater efficiencies

- Environmentally friendly and 100% recyclable

- Corrosion resistant

- Cost Effective

EXPERIENCE, INNOVATION & FLEXABILITY

EXPERIENCE, INNOVATION & FLEXABILITY

OUR SERVICES

MACHINING

- Drilling

- Milling

- Threading

- Tapping

- Broaching

- Assembly

Zamak Alloys

- #2 Zinc

- #3 Zinc

- #5 Zinc

- #7 Zinc

ZA ALLOYS

- ZA-8

- ZA 12

- ZA 27″

SURFACE PREP

- Tumble Deburring & Micro-finishing

- Sanding

- Shotblasting

- Polishing

- Buffing

FINISHING

- Dichromating

- Painting

- Powder Coating

- Chrome Plating

- Brass Plating

Production tooling

LEAD TIMES BASED ON PART COMPLEXITY

- H-13 Tooling – 10-14 weeks depending on complexity of part

- Production Samples –12-15 weeks

- Full Production – based on quantities

OUR SERVICES

MACHINING

- Drilling

- Milling

- Threading

- Tapping

- Broaching

- Assembly

Zamak Alloys

- #2 Zinc

- #3 Zinc

- #5 Zinc

- #7 Zinc

ZA ALLOYS

- ZA-8

- ZA 12

- ZA 27″

SURFACE PREP

- Tumble Deburring & Micro-finishing

- Sanding

- Shotblasting

- Polishing

- Buffing

FINISHING

- Dichromating

- Painting

- Powder Coating

- Chrome Plating

- Brass Plating

Production tooling

LEAD TIMES BASED ON PART COMPLEXITY

- H-13 Tooling – 10-14 weeks depending on complexity of part

- Production Samples –12-15 weeks

- Full Production – based on quantities

NEW IDEAS, FROM CONCEPT TO CASTING

NEW IDEAS, FROM CONCEPT TO CASTING

Seeking A Career?

Apply Today!

Seeking A Career?

Apply Today!

Contact BRYAN DIE CAST PRODUCTS TODAY!!!

Contact Bryan Die Cast Products Today!!!

Request QUOTE

If you would like us to quote your project or have additional questions for us regarding our ability to serve your needs, please fill out and return the form below.